GLDRR was the senior design project I worked on with Drew Nemeth and Victor Taksheyev from fall 2021 to spring 2022. The project aimed to solve a problem that we have frequently encountered when recovering high-power rockets, especially those that have reached higher altitudes. Wind conditions can cause rockets to drift miles away from the launch site, resulting in a lengthy and difficult recovery process. Traditional recovery methods such as dual-deployment and GPS tracking can help reduce these issues but become inadequate depending on weather conditions and the max altitude of the rocket. GLDRR addresses these problems through a self-contained system that will guide the rocket from apogee to established GPS coordinates at a safe distance from the launch site.

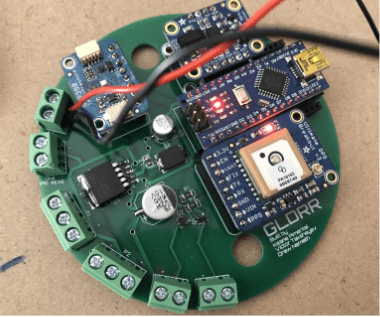

The heart of GLDRR consists of a custom-designed PCB outfitted with an accelerometer, GPS, altimeter, microcontroller, and screw terminals for the batteries, servos, and camera. This configuration has been designed to fit in the standard coupler avionics bay used in most high-power rockets.

GLDRR provides control by determining both the desired heading (toward predetermined coordinates) and the current heading. The microcontroller then uses the servos to steer the system and bring the current heading to the desired heading. A more detailed explanation of the electronics and control system can be found here on Victor’s website.

Testing of GLDRR was done at the component level before eventually combining everything together for a full hardware-in-the-loop test. The PCB was soldered together and checked out to ensure voltages and resistances were as expected. Then the sensors were attached to a drone to check if we were receiving accurate data. A primitive version of the full system was used in drop tests to tune the control authority of the servo and parafoil. With each component tested, the full system was integrated into a smaller “Return To Sender” rocket for full hardware-in-the-loop testing. “Return to Sender” is a small 34-inch long airframe designed to launch on L1 motors (H and I impulse class) to an altitude of approximately 1000-1500 ft. We launched Return to Sender at Jean Dry Lakebed and successfully recovered it approximately 200 ft from the launch pad.

After presenting our work at UNLV’s Senior Design Competition, we received the Commercial Potential Award and Grand Prize. Current plans are to continue testing the system on different airframes and motors to ensure its usability within the HPR community.