The first project I worked on with SEDS UNLV was the payload for our chapter’s rocket competing in the 2019 Spaceport America Cup. The payload was also entered into the Space Dynamics Laboratory (SDL) Payload challenge running concurrently with the SA Cup. It was required to meet the 3U CubeSat size requirements (where 1U is a 10x10x10 cm cube) and a weight of 8.8 pounds. The concept of the payload was to demonstrate the feasibility of deploying an inflatable habitat that could be used in future human Mars missions. Such a concept would save time in construction compared to traditional habitats and could even be launched ahead of time similar to the Ares missions in The Martian.

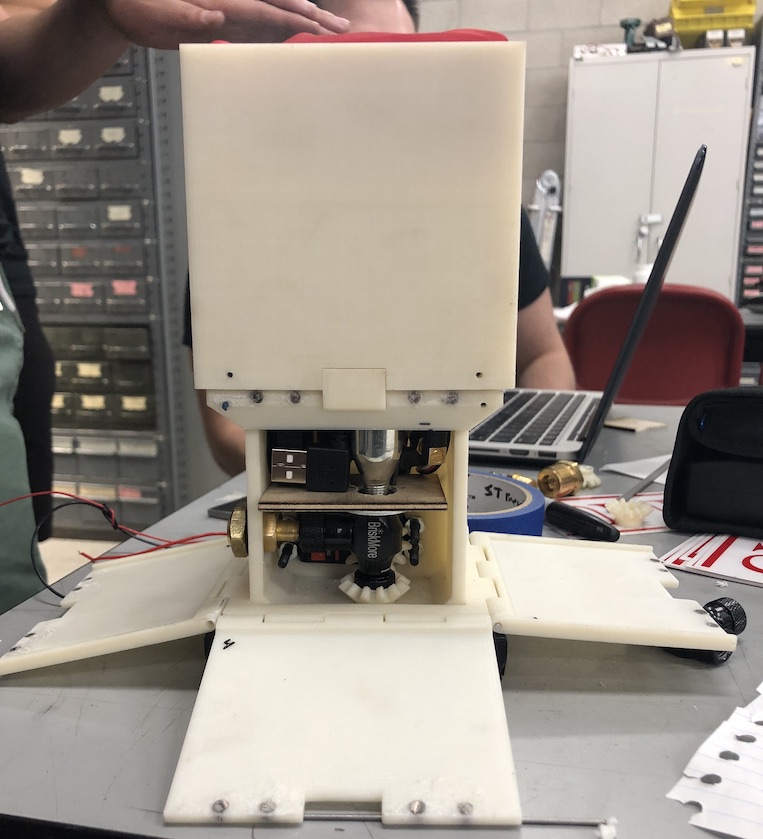

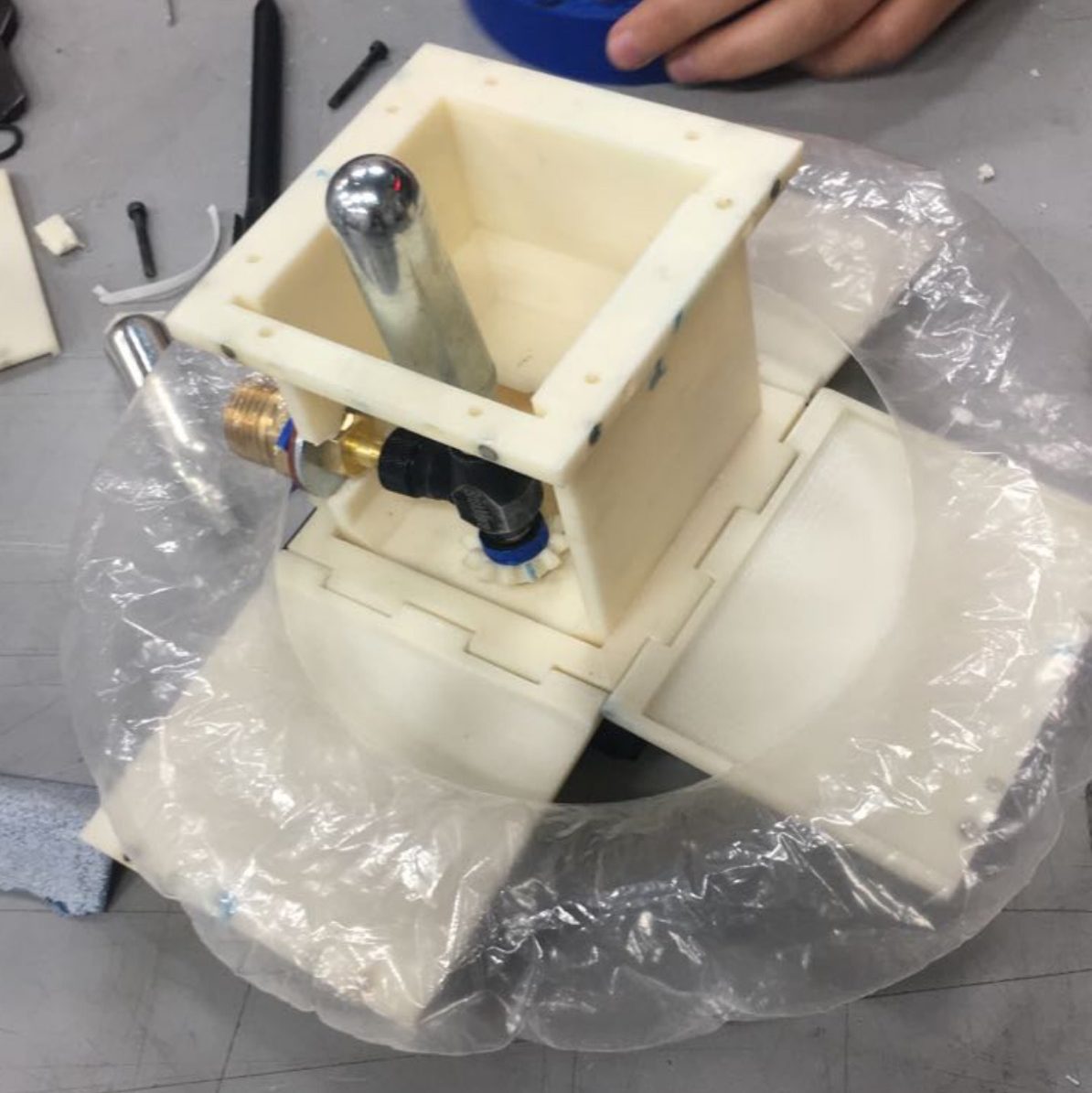

The above 3 pictures depict the 3 different cubes that comprised our inflatable habitat payload. The upper two units were connected together and contained the CO2 canister, habitat, avionics, and parachute. The structure was 3D printed out of ABS in order to save weight which would be essential for descent using a 24″ parachute. The bottom section of the deployable 2U was printed out of Ninja Flex TPU, a flexible and “squishy” material that would cushion the impact on landing. With the upper 2U section needing to be as lightweight as possible for recovery (weighing only about 2 pounds), the remaining ~6 pounds needed to be put into the bottom 1U cube. I solved this problem by fabricating the bottom 1U cube out of steel plates that were welded together. This cube was fixed into the body of the rocket, allowing us to meet the weight requirements and not worry about a ~6-pound chunk of steel falling from the rocket.

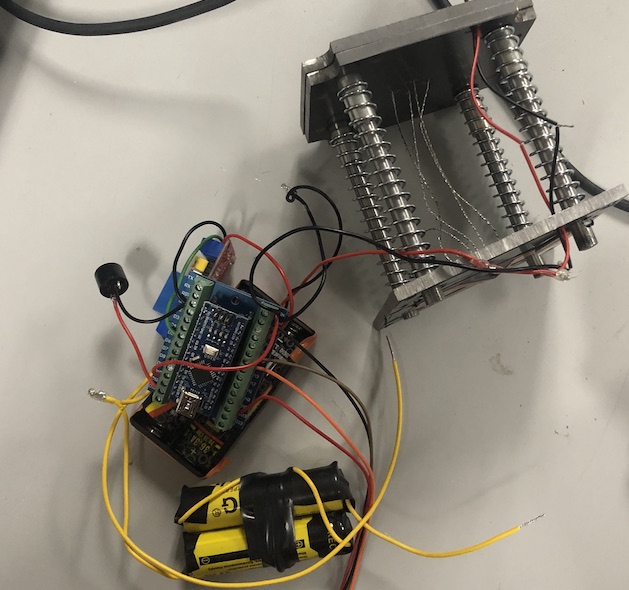

I also developed the spring-launch mechanism used to eject the upper 2U payload out of the rocket. One of the concerns was the orientation of the upper stage of the rocket during descent under drogue. We needed to ensure that the payload would deploy no matter the orientation during descent. To do this, I came up with the idea to use springs to force the payload out of the rocket. I found springs of sufficient strength to push the ~2-pound payload out of the rocket; we used nichrome wire to secure and then trigger the mechanism after being triggered by the electronics. It is worth noting that the mechanism worked successfully during testing but could not deploy out of the rocket as the nose cone itself did not deploy. The team attributed this issue to dust increasing the friction between the shoulder and the rocket body.