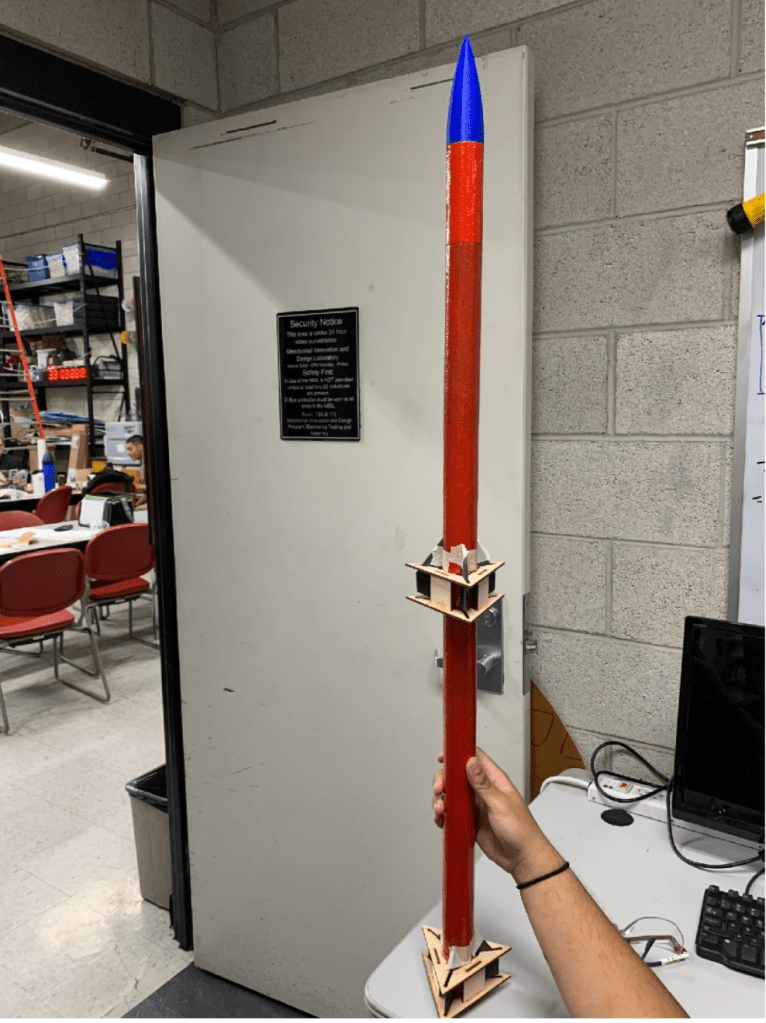

The University Student Rocketry Challenge (USRC) was a project which aimed to develop a multi-stage rocket to reach the highest altitude possible with a 640 N⋅s impulse limit.

The booster and sustainer body tubes were made of a single ply of fiberglass tubing, which would minimize the mass of the rocket.

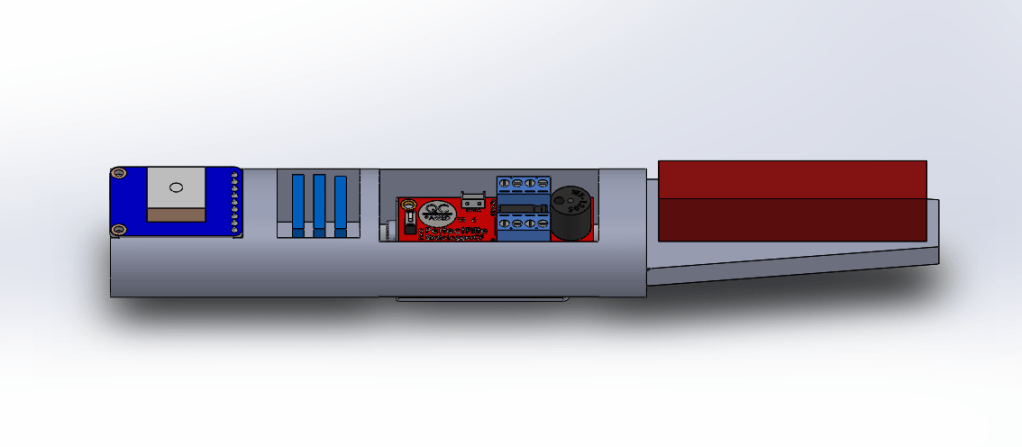

For this project, I was tasked with designing and manufacturing an avionics bay to sit in the coupler and nose cone of the upper stage of the rocket.

To begin designing the avionics sled, I first obtained a list of all the recovery and tracking electronics from the recovery team. These were the APRA altimeter, Stratologger, XBee-Pro, Adafruit Ultimate GPS, TinyDuino, Timer, and LiPo and 9V batteries. I then found SolidWorks models of these electronics and modeled my own based off of physical measurements where models could not be found. One of the greatest challenges of this project was fitting all of the required electronics in such a small volume. With the coupler and nose cone, the available volume was a cylinder approximately 34 mm in diameter and 210 mm long.

First, I created a preliminary fit check in SolidWorks and ran an interference check to see where any adjustments were needed. Then the model was 3D-printed in PLA and a physical fit check was performed for any other changes. One concern the recovery team had was running wires from the batteries to the various electronics. I then adjusted the design to include holes where possible as well as standoff mounting points for the XBee-Pro and APRA altimeter. The final physical model can be seen below. On the day of the rocket launch, there were issues with the Stratologger misfiring our pyrotechnic deployment charges and the team decided not to launch. The rocket is currently built but is awaiting a new launch opportunity.